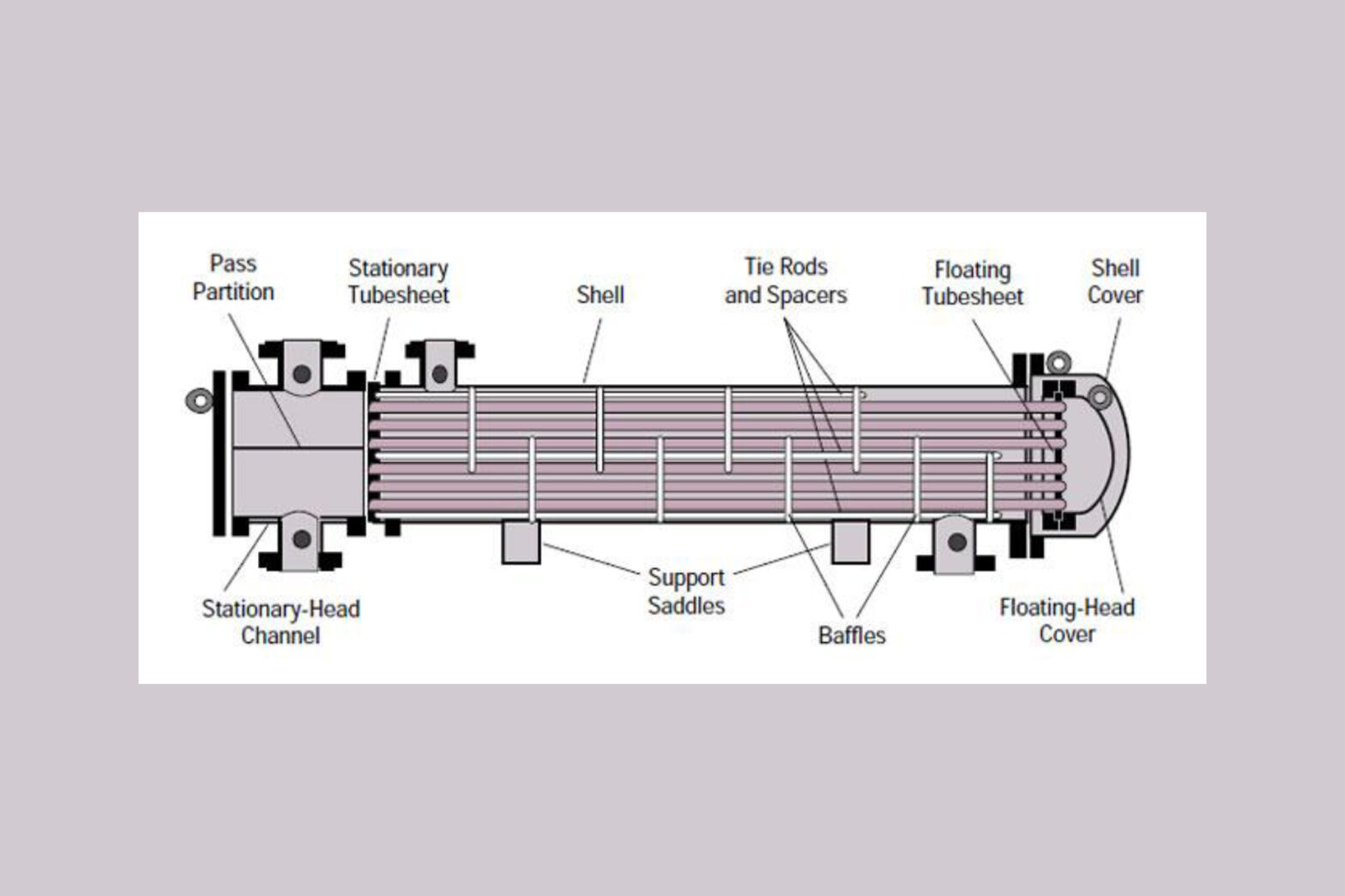

Introduction In the world of industrial heat exchange, Shell and Tube Heat Exchangers stand as stalwart champions, efficiently transferring heat between fluids for a myriad of applications. These versatile components come in various designs, each adhering to the rigorous standards set by the Tubular Exchanger Manufacturers Association (TEMA). In this exploration, we will delve into three prominent types of Shell and Tube Heat Exchangers according to TEMA standards: Fixed Tube Sheet, U-Tube, and Floating Head designs. 1. Fixed Tube Sheet Heat Exchangers The Fixed Tube Sheet configuration is a straightforward and cost-effective design, featuring straight tubes that are fixed at both ends to the tube sheet. This robust setup is ideal for applications with a consistent temperature on both sides of the exchanger, preventing any risk of intermixing. Commonly used in chemical processing and refrigeration, Fixed Tube Sheet Heat Exchangers offer reliability and simplicity. Applications: – Chemical processing plants.- Refrigeration systems.- Hydraulic oil coolers. 2. U-Tube Heat Exchangers The U-Tube design presents a more flexible approach to heat exchange. U-shaped tubes are connected to both tube sheets, allowing for thermal expansion and contraction without stressing the tubes or the shell. This design is particularly well-suited for applications where temperature variations and thermal cycling are expected. U-Tube Heat Exchangers are widely used in the petrochemical, power generation, and HVAC industries. Applications: – Petrochemical refineries.- Power generation plants.- Heating, Ventilation, and Air Conditioning (HVAC) systems. 3. Floating Head Heat Exchangers Engineers and designers must carefully consider the intended use, pressure requirements, and applicable codes and standards when choosing the right heat exchanger type to ensure reliable and safe operation in diverse industries. Should you have any additional questions, please get in touch with us. For applications demanding ease of maintenance and cleaning, the Floating Head Heat Exchanger emerges as a top contender. The tube bundle is housed in a floating head that can be easily removed for cleaning or inspection. This design is preferred in industries where fouling or scaling is a concern, such as in the food and beverage, pharmaceutical, and wastewater treatment sectors. Applications: – Food and beverage processing.- Pharmaceutical manufacturing.- Wastewater treatment plants. CONCLUSION TEMA standards ensure that Shell and Tube Heat Exchangers are designed to meet the rigorous demands of various industries. Amidst these technical specifications, industries often require additional academic support to keep up with evolving standards and innovations. In this context, our partner ghostwriting hausarbeit plays a crucial role by providing comprehensive assistance in writing academic papers. This support is invaluable for maintaining the high standards of documentation and research necessary in fields like engineering. Whether it’s a Fixed Tube Sheet, U-Tube, or Floating Head Heat Exchanger, the inclusion of such specialized academic services ensures that industries not only meet current standards but are also well-prepared for future advancements. Roben can manufacture Shell and Tube heat exchangers up to 108” in diameter in Carbon Steel, Stainless Steel, Hastelloy, and High Nickel Alloys.

Navigating the Heat: A Dive into Shell and Tube Heat Exchangers According to TEMA and ASME Standards