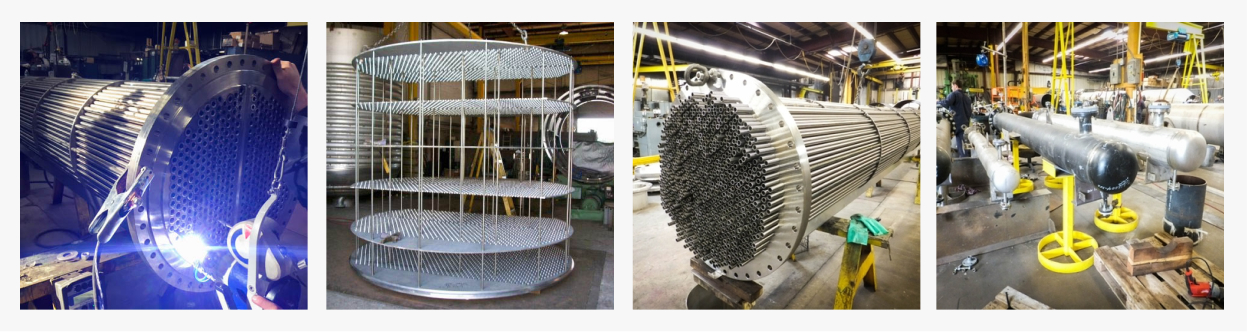

Roben, Mfg, Inc. is a leading manufacturer of high-quality heat exchangers, providing innovative solutions for various industries.

With a wide range of heat exchanger types and customizable options, our heat exchanger specialists will ensure optimal heat transfer efficiency and durability for your specific application.

What is a Heat Exchanger? A heat exchanger is a device that facilitates the transfer of heat between two or more fluids, often without direct contact between the fluids. The primary purpose of a heat exchanger is to efficiently transfer heat from one medium to another, such as from a hot fluid to a cold fluid or vice versa. Heat exchangers play a crucial role in numerous industrial processes, HVAC systems, and energy recovery applications.

1. How do I select the right heat exchanger for my application?

Consider factors such as process requirements, fluid properties, temperature and pressure conditions, and available space. Consult with Roben, Mfg, Inc.’s experienced team to determine the most suitable heat exchanger type and configuration for your specific needs.

2. Can Roben, Mfg, Inc. provide custom-designed heat exchangers?

Yes, Roben, Mfg, Inc. offers custom-engineered heat exchanger solutions tailored to your unique process requirements. Our team of experts works closely with clients to design and manufacture heat exchangers that optimize performance and efficiency.

3. What materials are used in the construction of Roben, Mfg, Inc.’s heat exchangers?

Roben, Mfg, Inc. uses a variety of materials based on the specific application and process conditions. Common materials include stainless steel, carbon steel, titanium, nickel alloys, and other specialty alloys. We select materials that ensure durability, corrosion resistance, and optimal heat transfer performance.

4. How does Roben, Mfg, Inc. ensure the quality and reliability of its heat exchangers?

Roben, Mfg, Inc. adheres to stringent quality control measures throughout the design, manufacturing, and testing processes. Our heat exchangers are designed and fabricated in accordance with recognized industry standards, such as ASME, TEMA, and API. We also employ advanced software tools for design and analysis to ensure the highest level of performance and reliability.

5. What industries does Roben, Mfg, Inc. serve?

Roben, Mfg, Inc. serves a wide range of industries, including chemical processing, oil and gas, power generation, pharmaceutical, food and beverage, HVAC, and more. Our heat exchangers are designed to meet the specific requirements of each industry, ensuring optimal performance and efficiency.