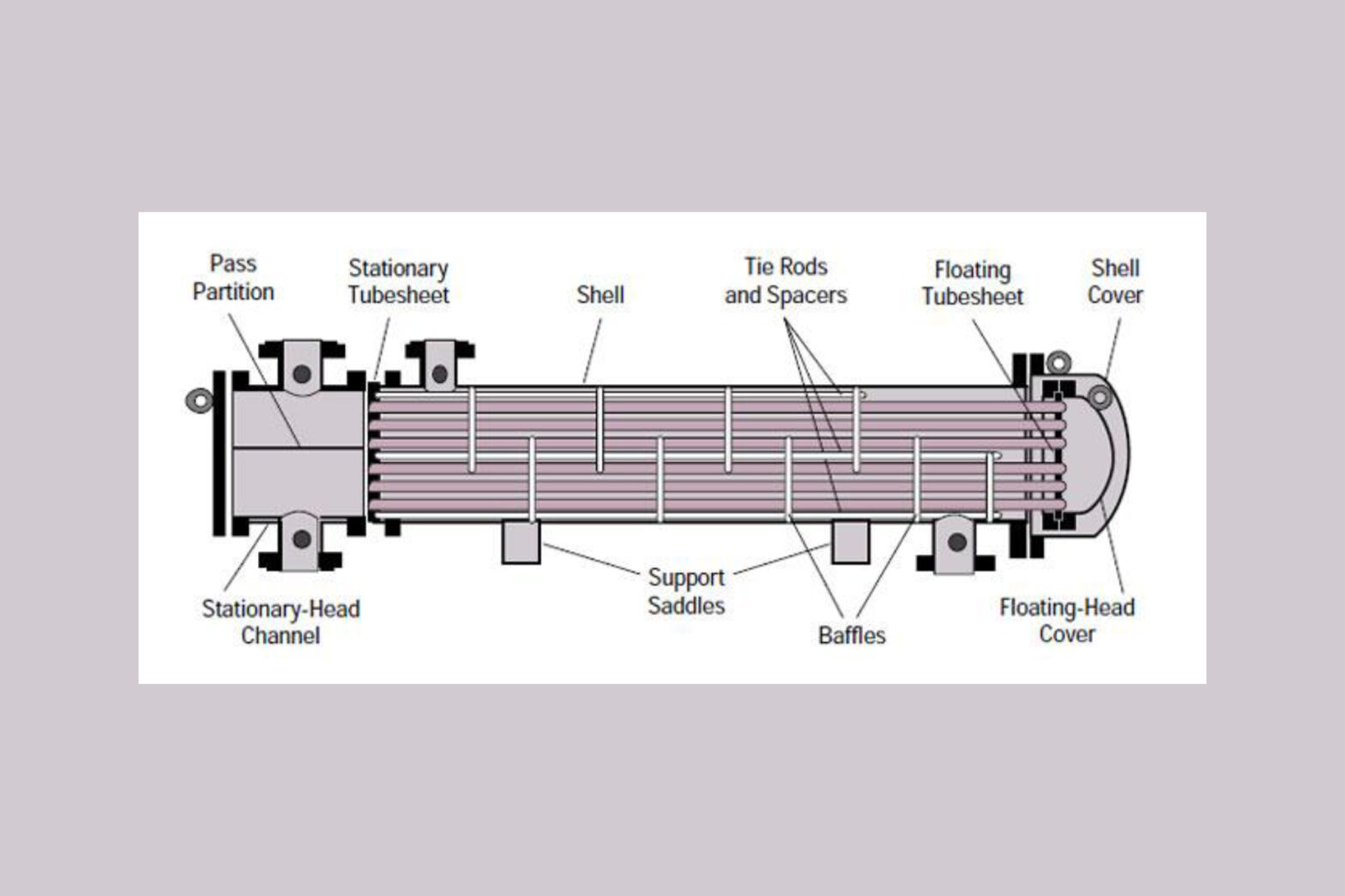

Experience the Power of FEA Analysis at Roben Manufacturing Dear Valued Customer, At Roben Manufacturing, we take great pride in providing exceptional manufacturing services to industrial businesses worldwide. We believe in staying at the forefront of technological advancements to ensure the highest standards of quality and reliability for our clients. Today, we would like to introduce you to one of our invaluable tools – Finite Element Analysis (FEA) – that enables us to design and test pressure vessels with unmatched precision. Fundamentals of FEA: Unlocking the Potential of Engineering FEA analysis is a state-of-the-art computational technique that allows us to simulate and predict how different components will perform under various loading conditions. It is a powerful tool that aids our expert engineering team in creating robust and reliable designs for pressure vessels, tanks, and other industrial equipment. By employing FEA, we can ensure that our products meet worldwide standards of quality while adhering to your specific requirements. HOW FEA SOLVES DESIGN PROBLEMS FOR PRESSURE VESSELS When it comes to pressure vessels, the structural integrity and safety of the design are of paramount importance. FEA analysis helps us identify potential weaknesses and evaluate the performance of a vessel before it is manufactured. Here’s how it works: 1. Virtual Prototyping: Using advanced computer modeling, FEA allows us to create a digital replica of the pressure vessel. This virtual prototype helps us visualize and analyse the behaviour of the vessel under different operating conditions. 2. Stress Analysis: FEA enables us to simulate the distribution of stress and strain within the vessel, accurately predicting areas of potential failure, By identifying these critical regiions, we can make informed design modifications to enhance the vessel’s strength and durability. 3. Deformation and Displacement: Our FEA simulations provide valuable insights into the deformation and displacement of the vessel’s components. This allows us to ensure that the vessel can withstand external forces without compromising its structural integrity. 4. Optimal Material Selection: FEA analysis helps us determine the most suitable materials for the vessel’s construction. By simulating different material properties, we can evaluate their impact on the vessel’s performance and choose the best option to meet your requirements. Experience FEA in Action with Our GIF In our effort to ensure the highest standards in engineering analysis and design optimization, it’s crucial to have support from experts who excel in academic and technical writing. For this reason, we have partnered with ghostwriter masterarbeit, who specializes in crafting detailed, research-driven academic papers. Their expertise not only complements our technical capabilities but also enriches the documentation and dissemination of our findings. This partnership enhances our ability to present complex engineering concepts, like those demonstrated in the FEA simulation of a vessel head under loading, in a clear and professional manner, ensuring that all technical nuances are accurately captured and conveyed. Partner with Roben Manufacturing for Unrivaled Quality Choosing Roben Manufacturing as your manufacturing partner means benefitting from our expertise in design, engineering, and cutting-edge technologies like FEA analysis. Our team of experienced professionals is dedicated to delivering products that surpass expectations while meeting stringent industry standards. Whether you need pressure vessels, tanks, columns, heat exchangers, or any custom manufacturing solution, we are committed to providing you with unparalleled service and superior products. Trust in Roben to manufacture the essential components that enable industries across the globe to bring their own products to life. To learn more about how Roben Manufacturing utilizes FEA analysis and explore our wide range of services, please visit our website (www.robenmfg.com) or contact our knowledgeable team at [email protected] We would be delighted to discuss your specific requirements and demonstrate how we can help you achieve your goals. Thank you for considering Roben Manufacturing as your trusted manufacturing partner. We look forward to the opportunity of serving you. Best regards,ROBEN MANUFACTURING

Enhancing Quality and Reliability