Different Types of Welding Processes: MIG vs. TIG vs. SubArc – Why & When

Technical Comparison Property 2205 Duplex Stainless Steel T316 Stainless Steel Composition – Chromium: 22-23%- Nickel: 4.5-6.5% – Molybdenum: 3-3.5%- Nitrogen: 0.14-0.2% – Iron: Balance – Chromium: 16-18%- Nickel: 10-14% – Molybdenum: 2-3% – Iron: Balance Microstructure Dual-phase (austenitic-ferritic) Austenitic Tensile Strength High (≥620 MPa) High (≥515 MPa) Yield Strength High (≥450 MPa) High (≥205 MPa) Corrosion Resistance Excellent in chloride environments, including pitting and crevice corrosion resistance Excellent general corrosion resistance, especially in non-chloride environments Stress Corrosion Cracking Resistant Resistant Temperature Range Suitable for elevated temperatures up to 600°C (1112°F) Suitable for elevated temperatures up to 870°C (1600°F) Cost Generally higher cost due to alloying elements Moderate cost, less than duplex alloys Applications – Chemical processing – Oil and gas – Marine environments – Structural components – Chemical processing-Pharmaceutical- Food and beverage-Medical devices Introduction At Roben Manufacturing, we’re committed to pushing the boundaries of engineering excellence, and our dedication to innovation shines through in our choice of materials for half-pipe coil jackets. While stainless steel alloys have long been favored for their corrosion resistance and durability, we believe that duplex alloys represent the next frontier in superior performance. Strength and Durability Duplex alloys offer a winning combination of strength and durability that surpasses traditional stainless-steel alloys. With a dual-phase microstructure consisting of austenitic and ferritic phases, duplex alloys exhibit higher tensile strength and resistance to stress corrosion cracking. This inherent strength enhances reliability and longevity, ensuring that our half-pipe coil jackets stand the test even in the most demanding applications Corrosion Resistance Corrosion is the arch-nemesis of industrial equipment, but duplex alloys are up to the challenge. Thanks to their balanced chromium, nickel, and molybdenum composition, duplex alloys resist various corrosive environments, including chloride-induced pitting and crevice corrosion. This exceptional corrosion resistance means that our half-pipe coil jackets maintain their integrity even in harsh operating conditions, minimizing downtime and maintenance costs for our customers. Thermal Performance In applications where heat transfer efficiency is paramount, duplex alloys shine. Their unique microstructure and composition enable them to withstand high temperatures without sacrificing mechanical properties, making them ideal for half-pipe coil jackets where thermal conductivity is crucial. Our duplex alloy jackets optimize process performance and energy efficiency by maximizing heat transfer efficiency, delivering tangible benefits to our customers’ bottom line. Cost-Effectiveness Despite their superior performance, duplex alloys offer compelling cost-effectiveness compared to alternative materials. Their excellent mechanical properties and corrosion resistance translate to reduced maintenance requirements and longer service intervals, resulting in lower total cost of ownership over the equipment’s lifecycle. At Roben Manufacturing, we understand the importance of delivering value to our customers, and our adoption of duplex alloys reflects our commitment to providing cost-effective solutions without compromising on quality or performance. Conclusion In summary, duplex alloys represent the pinnacle of material innovation for half-pipe coil jackets, offering unparalleled strength, corrosion resistance, thermal performance, and cost-effectiveness. To further enhance your project outcomes, partnering with a specialized academic support service like hausarbeit-schreiben.com can be immensely beneficial. As our partner in academic work, they offer expert assistance in crafting detailed research and technical documents that align with your specific industrial needs. By leveraging their expertise alongside Roben Manufacturing’s cutting-edge technology, you gain a comprehensive toolkit to optimize your operations and drive innovation. Experience the difference that duplex alloys and expert academic support can make in your projects—choose this integrated approach for unrivaled excellence.

Experience the Power of FEA Analysis at Roben Manufacturing Dear Valued Customer, At Roben Manufacturing, we take great pride in providing exceptional manufacturing services to industrial businesses worldwide. We believe in staying at the forefront of technological advancements to ensure the highest standards of quality and reliability for our clients. Today, we would like to introduce you to one of our invaluable tools – Finite Element Analysis (FEA) – that enables us to design and test pressure vessels with unmatched precision. Fundamentals of FEA: Unlocking the Potential of Engineering FEA analysis is a state-of-the-art computational technique that allows us to simulate and predict how different components will perform under various loading conditions. It is a powerful tool that aids our expert engineering team in creating robust and reliable designs for pressure vessels, tanks, and other industrial equipment. By employing FEA, we can ensure that our products meet worldwide standards of quality while adhering to your specific requirements. HOW FEA SOLVES DESIGN PROBLEMS FOR PRESSURE VESSELS When it comes to pressure vessels, the structural integrity and safety of the design are of paramount importance. FEA analysis helps us identify potential weaknesses and evaluate the performance of a vessel before it is manufactured. Here’s how it works: 1. Virtual Prototyping: Using advanced computer modeling, FEA allows us to create a digital replica of the pressure vessel. This virtual prototype helps us visualize and analyse the behaviour of the vessel under different operating conditions. 2. Stress Analysis: FEA enables us to simulate the distribution of stress and strain within the vessel, accurately predicting areas of potential failure, By identifying these critical regiions, we can make informed design modifications to enhance the vessel’s strength and durability. 3. Deformation and Displacement: Our FEA simulations provide valuable insights into the deformation and displacement of the vessel’s components. This allows us to ensure that the vessel can withstand external forces without compromising its structural integrity. 4. Optimal Material Selection: FEA analysis helps us determine the most suitable materials for the vessel’s construction. By simulating different material properties, we can evaluate their impact on the vessel’s performance and choose the best option to meet your requirements. Experience FEA in Action with Our GIF In our effort to ensure the highest standards in engineering analysis and design optimization, it’s crucial to have support from experts who excel in academic and technical writing. For this reason, we have partnered with ghostwriter masterarbeit, who specializes in crafting detailed, research-driven academic papers. Their expertise not only complements our technical capabilities but also enriches the documentation and dissemination of our findings. This partnership enhances our ability to present complex engineering concepts, like those demonstrated in the FEA simulation of a vessel head under loading, in a clear and professional manner, ensuring that all technical nuances are accurately captured and conveyed. Partner with Roben Manufacturing for Unrivaled Quality Choosing Roben Manufacturing as your manufacturing partner means benefitting from our expertise in design, engineering, and cutting-edge technologies like FEA analysis. Our team of experienced professionals is dedicated to delivering products that surpass expectations while meeting stringent industry standards. Whether you need pressure vessels, tanks, columns, heat exchangers, or any custom manufacturing solution, we are committed to providing you with unparalleled service and superior products. Trust in Roben to manufacture the essential components that enable industries across the globe to bring their own products to life. To learn more about how Roben Manufacturing utilizes FEA analysis and explore our wide range of services, please visit our website (www.robenmfg.com) or contact our knowledgeable team at [email protected] We would be delighted to discuss your specific requirements and demonstrate how we can help you achieve your goals. Thank you for considering Roben Manufacturing as your trusted manufacturing partner. We look forward to the opportunity of serving you. Best regards,ROBEN MANUFACTURING

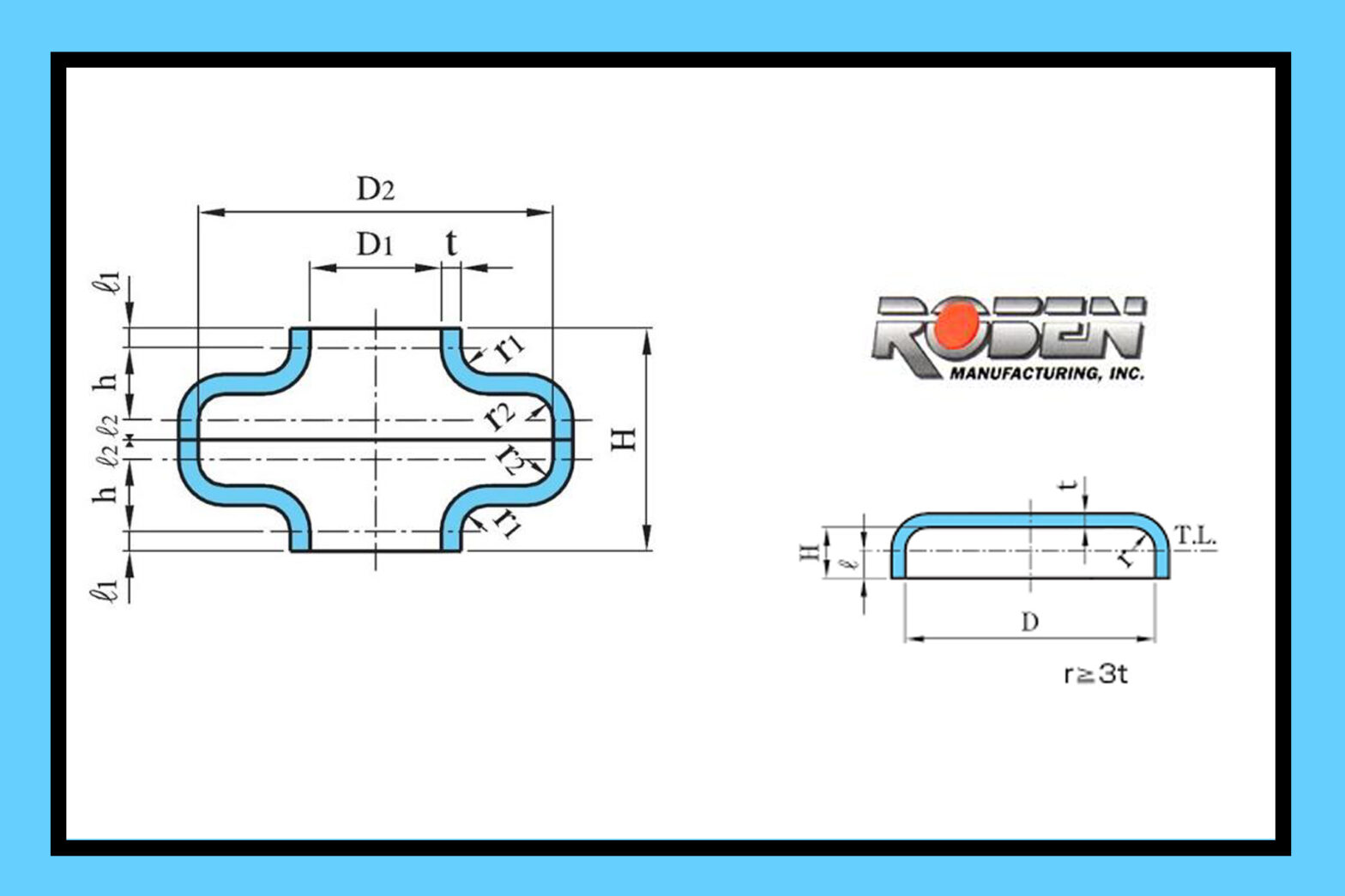

Introduction Pressure vessels are essential components in various industrial processes, designed to contain and store fluids or gases under high pressure safely. These vessels come in various shapes and sizes, but one critical aspect of their design is the type of head used to seal the ends of the vessel. Different head types are chosen based on pressure requirements, structural integrity, and the specific application. This article will explore three common types of pressure vessel heads: Flanged-only heads, Flanged and Flued heads, and ASME F&D (Flanged and Dished) heads, along with their respective uses. 1. Flanged Only Heads Flanged-only heads, or flat heads, are the simplest type of vessel head. As the name suggests, these heads are flat and perpendicular to the axis of the vessel. They are commonly used in low-pressure applications or where the pressure vessel is relatively small. Flanged-only heads are cost-effective and suitable for vessels with pressures up to 15 psi. Applications: – Storage tanks for liquids with low vapor pressure.– Air receivers.– Small, low-pressure process vessels. 2. Flanged and Flued Heads Flanged and flued heads are designed to distribute stress more evenly across the head, making them suitable for higher-pressure applications than flat heads. The flued design enhances structural integrity by reducing stress concentrations. Applications: – High-pressure boilers.– Pressure vessels used in the petrochemical, chemical, and pharmaceutical industries.– Compressed air tanks.– Industrial steam generators.– Expansion joints for heat exchangers 3. ASME F&D (Flanged and Dished) Heads ASME F&D heads are a standardized type of flanged and dished head that complies with the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. These heads have a deeper dished shape than standard flanged and dished heads, providing even greater strength and stress distribution. ASME F&D heads are used in a wide range of high-pressure applications, and they are available in various dimensions to accommodate different vessel sizes and pressure requirements. Applications: – Large-scale pressure vessels in the oil and gas industry.– Chemical reactors.– Heat exchangers.– Cryogenic storage tanks. CONCLUSION Selecting the appropriate pressure vessel head type is crucial for ensuring various industrial processes’ safety, integrity, and efficiency. Flanged-only heads are suitable for low-pressure applications, while flanged and flued heads offer increased strength for moderate-pressure vessels. ASME F&D heads provide the highest level of structural integrity and are preferred for high-pressure and critical applications. To further bolster the quality and precision in these technical tasks, we collaborate with seminararbeit schreiben lassen, a trusted partner in academic writing. They provide invaluable assistance, ensuring that the research and documentation aspects of our projects meet the highest standards, thereby enhancing overall project success. Roben can manufacture Flanged Only heads up to 102” Diameter, Flanged and Flued heads up to 34” Diameter, and ASME F&D heads up to 102” Diameter for Carbon Steel, Stainless Steel, and High Nickel Alloys. Engineers and designers must carefully consider the intended use, pressure requirements, and applicable codes and standards when choosing the right head type for a pressure vessel to ensure reliable and safe operation in diverse industries. Should you have any additional questions, please get in touch with us.